Wood shafting usually is available in various diameters, 5/16 inch, 11/32 inch, 23/64 inch and sometimes 3/8 inch. They usually come in spine weights that range in five pound increments, i.e. 60-65 pounds, 65-70 pounds, etc. The spine of the shaft is normally determined by measuring the amount of bend it exhibits when a two pound weight is placed in the centre of the shaft whilst it is suspended on two supports 26 inches apart.

You will have to try a number of different spine weight arrows to find which one will suit you. I mostly shoot laminated longbows of my own making and as a general rule of thumb I find it is better to have too much spine than not enough. For this reason I take my draw weight and then add ten to fifteen pounds of spine weight. For example, if I had a bow weight of 60 pounds then I would use shafts in the 70-75 pound spine range. Also if you have a long draw length, add another five pounds of spine weight for each inch of draw over 28 inches. However, when using my selfbows I find arrows equal in spine to the weight bow I'm shooting to work best.

As stated above you will have to find which arrow is best suited to your shooting style when using your bow. The spine arrows that work for me may not work for you. Only by trying arrows of differing spine, weight and diameter is it possible to find what bests suits your needs.

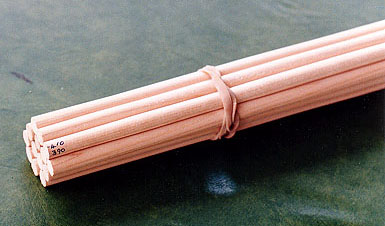

With your arrow requirements worked out you now have three options. You may purchase your arrows custom made from your preferred traditional archery dealer and negate the rest of this article. You may order your shafts already spined, weighed and graded, and skip the next three steps. Lastly you can order in bulk and do all the work yourself. Since we are dealing with making our own set of matched arrows I am going to continue as if you went with the last option.

I would suggest that you order at least a hundred shafts at a time. The reason for this is that unless you buy your shafts already graded - option two above - they are most likely going to vary greatly in both spine and weight. You may find that only half of the shafts will be matched to your preferred spine and weight.