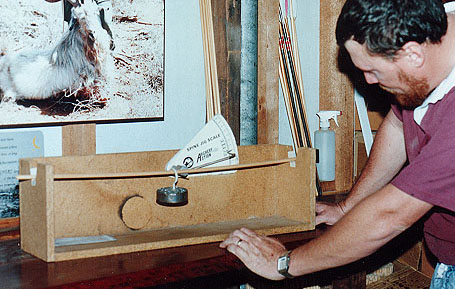

Spining and Weighing

Once graded it is time to spine the remaining shafts. Place a shaft on your spine tester and rotate it. You will notice that more often than not you will get a different reading when the grain runs horizontal as opposed to when it is running vertical. The shaft is usually stiffer when the grain is in the vertical position. It is very important that you spine all shafts with the grain. That is, the grain lines on the ends of the shaft should be running vertical from the 12 o'clock to the 6 o'clock position. The rift in the shaft should be in the 9 o'clock and 3 o'clock positions.

The rift of the shaft that is facing you when the shaft is placed in the spine tester will be pointing to the intended point end of your finished arrow. If you are right handed have the rift pointing left, and if you are left handed have the rift pointing right. By doing this you are ensuring that you are testing the spine (amount of bend) of the arrow in the direction in which it is going to be bending around the side of your bow when shot.

Spine each shaft and write the spine weight on the shaft near one end. When you have finished spining them all, you will notice that you have a broad range of different spine weight shafts before you. Place them into groups according to their spine, i.e. 60-65 pounds, 65-70 pounds, 70-75 pounds and so on. I have had the spine weights of a hundred shafts vary as much as 20 to 30 pounds and sometimes more.

The next step is to weigh each spined group of shafts. Write the weight of the shaft under where you wrote the spine weight. When you have done this you will notice that you have even more groups of shafts. The number of groups will depend on how accurate you want to be. I find a range of 20 grains, in any one group, to be acceptable but you can lower this to a 10 or even 5 grain range if you wish. You will see that the grain weights can easily vary 100 grains or more over the whole batch. Once you have the groups sorted, pick out the ones that suite you. The rest you can sell to someone else whose spine and weight requirements are different to yours. You are now ready for the next step.